Baldwin Technology experts to introduce “Diamond Standard” for corrugated production efficiency at FEFCO Technical Seminar Spotlight

St. Louis (October 9, 2023) – Baldwin, the leading global manufacturer and supplier of innovative process-automation equipment, parts, service and consumables for the printing, packaging, textile, plastic film extrusion and corrugated industries, will be demonstrating its corrugated-industry leadership by shing a “Diamond Standard” on cleaning and drying revelations at the forthcoming FEFCO Technical Seminar (Centre de Congres de Lyon, Lyon, France, October 25-27, 2023).

During a highly-coveted October 25 Spotlight Spot at FEFCO, Baldwin will present a provocative technical presentation entitled “Fool’s Gold. Why All That’s Gold Doesn’t Glitter. – Adopt the ‘Diamond Standard’ for Efficiency,” led by Dennis Behnisch, Baldwin’s Germany-based Engineering and R&D Leader.

FEFCO is the European Federation of Corrugated Board Manufacturers, the non-profit organization representing the interests of the industry across Europe and addressing a wide range of issues, from technical topics to economic considerations.

Baldwin’s presentation will be centered on its how the users of its combination of Diamond IR and FlexoCleanerBrush can glean value from these technology advancements

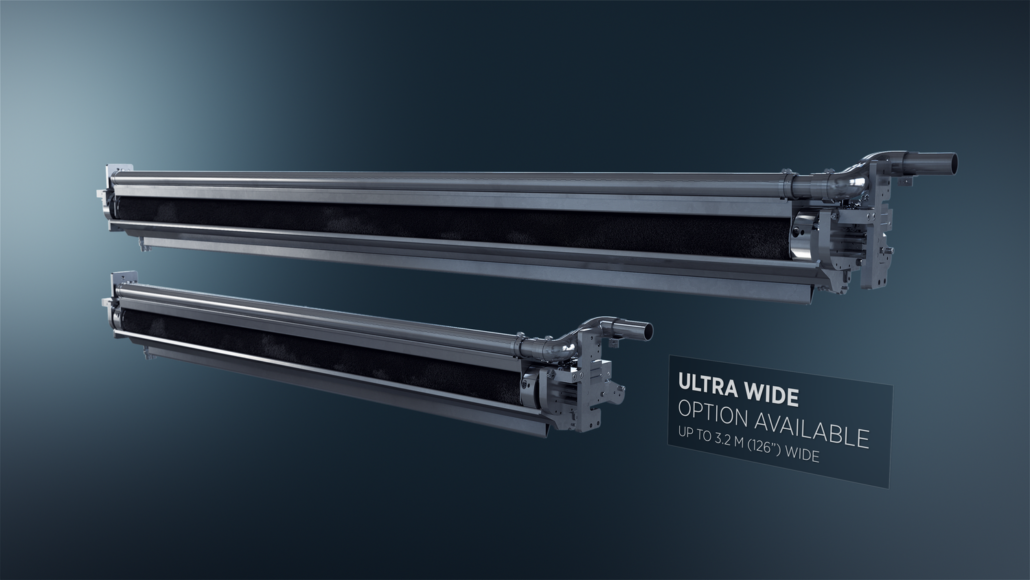

Baldwin’s recently-introduced Ultra Wide FlexoCleanerBrush has garnered wide market favor and adoption. It is a fully automated flexo plate-cleaning system that can be up to 126 inches (3.2 meters) wide. As Baldwin’s flagship solution to enhance print quality and improve worker safety in corrugated printing, the system automatically removes dust and contamination from the plate in seconds during production, without stopping the press.

It also performs full end-of-job plate cleaning and drying in under four minutes, enabling increased capacity, improving operator injury and saving thousands of dollars per year in consumables spending.

Baldwin will also explore its FlexoDry Infrared (IR) drying system. Developed to maximize press throughput, boost production speeds and reduce energy consumption, the FlexoDry system utilizes Diamond-IR lamps to focus powerful IR radiation. These lamps use a unique ceramic reflector that directs all light to the substrate, resulting in 30% energy savings when compared with other IR lamps.

In addition to these technological advancements, to further support the overall corrugated industry Baldwin has launched www.printenomics.com. A corrugated-specific Ebook featuring a dedicated resource center, it houses discrete industry organization and trade publication links and a host of podcasts and instructional guides to maximize profitability in the corrugated space

In consultation with its customers, industry experts, and in-house engineering team – along with a review of the latest reporting – “From Beast to Beauty” explores four primary trends that will impact box-making facilities: E-commerce, Brand Protection, Sustainability, and Labor Challenges.

“With the incredible explosion in demand for corrugated materials, it’s no secret that box plants are being squeezed to get more capacity and quality out of their existing equipment. When you add to this the scarcity of qualified operators to run production, the entire industry requires smart automation that enables efficiency,” said Behnisch. “Here at Baldwin ,we possess a long-held knowledge of the corrugated industry – we have pioneered technologies that our customers demand, and that is what the audience can learn more about at our spotlight talk.”

ABOUT BALDWIN TECHNOLOGY COMPANY INC.

Baldwin Technology Company Inc. is a leading global manufacturer and supplier of innovative process-automation equipment, parts, service and

consumables for the printing, packaging, textile, plastic film extrusion and corrugated industries. As a total solutions provider, Baldwin offers our

customers a broad range of market-leading technologies, with a focus on improving the economic and environmental efficiency of production

processes. Through a global footprint of 21 company-owned locations and an extensive network of partners, our customers are supported globally,

regionally and locally by dedicated sales and service team members who add value by forming long-term relationships. Baldwin is privately owned by

BW Forsyth Partners, a Barry-Wehmiller company. For more, visit baldwintech.com.

ABOUT BW FORSYTH PARTNERS

BW Forsyth Partners is the investment arm of multibillion-dollar global manufacturing and engineering consulting firm Barry-Wehmiller. Established in

2009, BW Forsyth Partners blends Barry-Wehmiller’s unparalleled legacy of value creation and people-centric culture development with keen investing

experience to help companies realize their true potential. With a focus limited to areas known well, BW Forsyth Partners seeks to partner with

leadership teams to acquire small- to middle-market companies in the capital and component equipment, and professional services sectors. In each of

our operating companies, BW Forsyth Partners deploys operational improvements and strategy development without compromising the autonomy,

strategic vision and entrepreneurial spirit of their leadership teams. For more information, visit bwforsyth.com.