The Corrugating Machinery Division of Mitsubishi Heavy Industries America, a leading supplier of corrugating and box-making machinery, is launching three new equipment and service offerings for North America at SuperCorrExpo® (Booth #1631, Orlando, Florida, August 8-12).

Dedicated to serving the corrugated industry, the company’s latest additions to its industry-leading portfolio are the MC-100 Flexo Folder Gluer, the MPF Prefeeder for EVOL, and new capabilities for its EVOL AR Remote Assistance Augmented Reality Program. The trio of advancements is engineered to maximize efficiency, productivity and profitability.

“Our technology-development pipeline is a deep one and the result of constant collaboration with our customers,” said Shoji Isoai, President, MHIA Corrugating Machinery Division. “This on-going feedback loop helps us to produce the equipment and service offerings that meet and exceed the growing needs of box-making facilities across North America.”

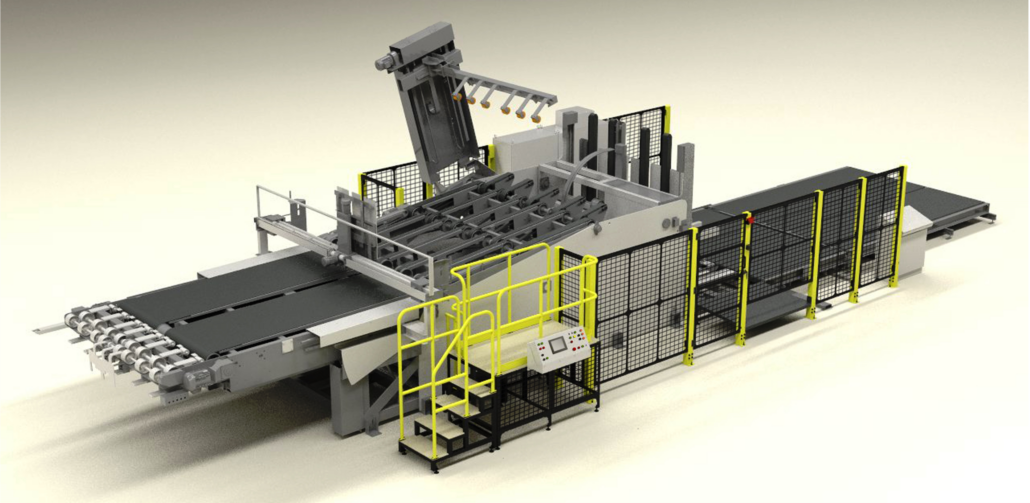

- The new MC-100 is a state-of-the-art Flexo Folder Gluer that features ease of operation and enhanced quality-control for plant personnel. Introduced in Japan in 2020, the MC-100 produces less downtime through easy technician access via elevated platforms. Its innovative stop and start wheel feeder provides non-continuous feeding, ensuring 100% alignment and quality control. Top production rate is 300 BPM.

- The new MPF Prefeeder ensures faster throughput and the front-of-line reliability required to keep the company’s premium line of EVOL box-making equipment functioning with maximum efficiency. In productive use across multiple facilities in the EU, the MPF Prefeeder is now available for customers in North America.

- Work Instructions represent the latest evolution of the company’s EVOL AR Remote Assistance Augmented Reality Program. With some customers reporting an impressive 50% reduction in downtime, EVOL AR allows North America-based plant managers, technicians, and engineers to quickly and efficiently share and resolve issues in real-time from their facilities.

Using Work Instructions, users will have access to a library of AR content covering everything from basic machine calibrations, wear part replacements, lubrication, and additional material Using a 3D model of the machine, MHIA is able to build much more intuitive reference manuals and training materials.

EVOL AR will be explored in further detail by Steve Laslo, the company’s Digital Technology and Training Supervisor, as part of SuperCorrExpo’s TechTalks: What’s New on Wednesday, August 11 at 9:15 a.m. “EVOL AR is a massive step forward in how the corrugated industry handles service issues and reference materials,” said Laslo.

Joining Laslo are the company’s sales, service, and technical team members. They will be on hand at Booth #1631 to introduce the benefits of the three new offerings, field customer questions, discuss collaboration opportunities, and share their latest insights.

“If the challenges of the past 16 months have taught us anything, it’s that we’re so proud to be a member of this remarkably resilient and creative industry,” said Hiroyuki Kikumoto

Senior Vice President, Sales, MHIA Corrugating Machinery Division. “We’re excited to connect and reconnect in person with the entire supply chain and work with them to keep advancing the industry.”

More information: www.mhicorrugating.com